Necessity of complete backflow prevention circuit

Many mobile devices equipped with secondary batteries need to support battery supply from external such as AC/DC adapters and USB, etc. an external terminal for this purpose is required.

When there is no external power supply for such a device, it is necessary to prevent the voltage of secondary batteries from being output to an external terminal from the standpoint of terminal corrosion prevention and safety.

A charger IC for general lithium batteries has a built-in backflow prevention function and it is unnecessary to consider voltage output to external terminals.

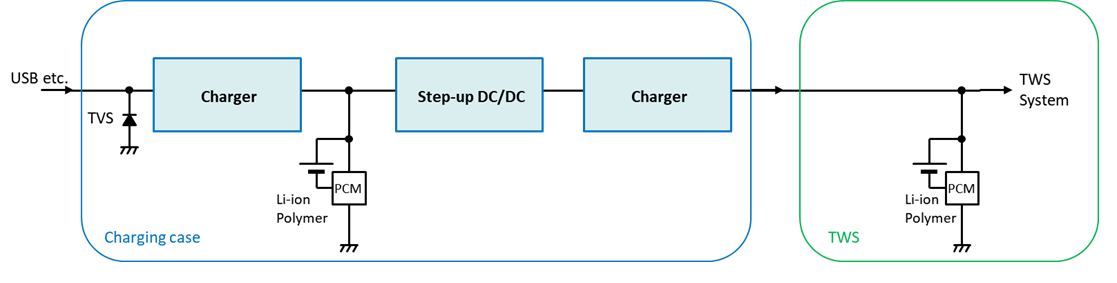

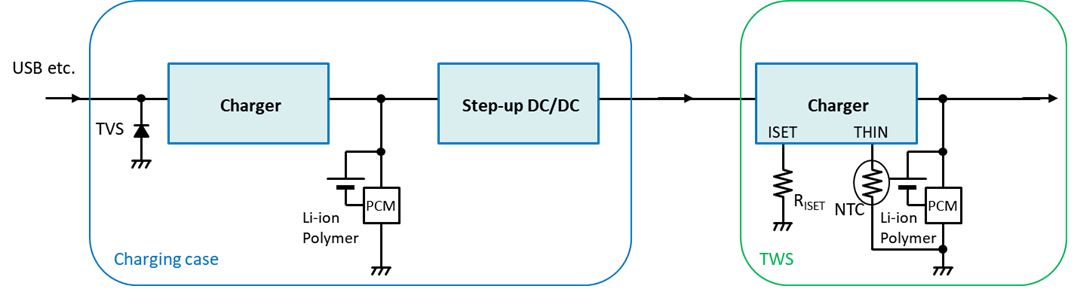

However, for charger IC that has no built-in backflow prevention function or devices for which a device with a built-in charger IC and a device equipped with a battery are separated, it is necessary to take measures against voltage output to external terminals.

Problems and purposes

A simple method as measures against voltage output to external terminals is using a discrete diode.

However, with a discrete diode, VF voltage drop in forward direction or current leakage at reverse bias occurs.

Especially when the capacity of secondary battery is small, the battery level of the secondary battery decreases if the current leakage at reverse bias is large. This is a fatal problem.

For this reason, a complete backflow prevention circuit with low current leakage is necessary.

How to realize

The simplest and most effective measure is configuring a complete backflow prevention circuit using the ideal diode IC.

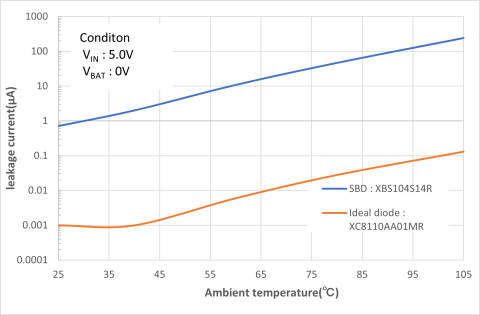

For just reducing the current leakage, using PN diode instead of schottky barrier diode can reduce the current leakage. However, VF of PN diode is about 0.7 to 1.0 V and the voltage drop when power is supplied from external power supply is very large.

In addition, VF od schottky diode is small; 0.3 to 0.5 V, however, the current leakage is large; uA to 10 uA order. Thus, the current consumption of the battery cannot be reduced.

With the ideal diode IC, it is possible to suppress leakage current to 1 μA or less even considering the current consumption, so the complete backflow prevention circuit with optimum characteristics can be easily configured.

Especially when a device with built-in charger IC and a device equipped with battery is separated, the voltage drop becomes large and it affects charging of secondary battery if VF of diode is large. It is necessary to use an ideal diode IC with small VF or configure a circuit by controlling FET with other circuit.

In addition, it is also possible to use a load switch IC equipped with a backflow prevention function.

However, there are load switch ICs that can prevent backflow only in standby status depending on the product. Thus, it is necessary to select an appropriate load switch IC.

Advantages

- Low current leakage can minimize battery discharge

- Low output voltage fluctuation due to small VF can contribute to the stable operation of the system

Disadvantage

- Number of products is small / less compatible compared to discrete diode

Overview of operation

Operation and characteristics of backflow prevention circuit have been actually compared for each type.

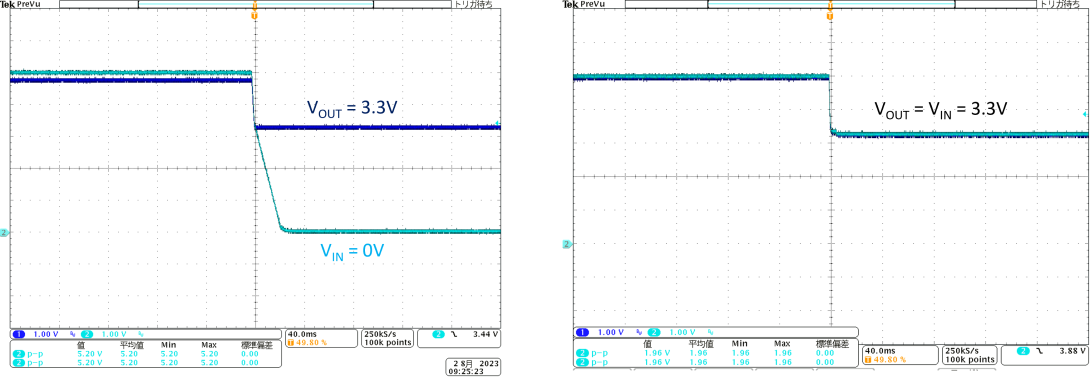

1.Backflow prevention characteristics

The image shown below is an oscilloscope waveform when VIN is changed from 5 V to OPEN with 3.3 V applied to VOUT. For the waveform with ideal diode on the left side, the voltage of VIN terminal is 0 V, however, for the waveform without ideal diode, the voltage of VOUT terminal is output to VIN terminal.

2.Current leakage

The image shown below compares the current leakage of ideal diode and SBD at each ambient temperature. The current leakage of the ideal diode is about 0.1 μA even at high temperatures, however, for SBD, leakage current of 100 μA or more is flowing.

Conclusion

This paper explained that using the ideal diode IC could easily configure the complete backflow prevention circuit.

With a load SW, etc. equipped with backflow prevention function, the voltage on output side may be output to the input side depending on the backflow prevention control system of the product. It is necessary to keep this in mind.