A new generation of Li rechargeable, semi solid state batteries which typically operate with a nominal voltage between 2.2V and 2.4V are now becoming common. These batteries can often be charged with a Constant Voltage using a simple LDO Voltage Regulator and the charging Voltage is normally set at a fixed level between 2.5V to 2.7V.

Utilising these batteries, a designer can realise a simple charging solution without the complexity normally associated with dedicated Li-ion charger IC. Our example solution circuit illustrates how this can be achieved. Applications include, powering small IoT devices and as a battery back up for industrial devices.

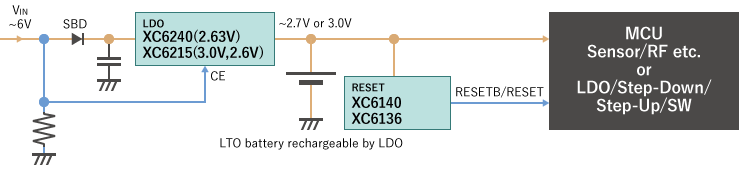

Block Diagram

| Block diagram | Requirements | Recommended ICs | Features |

|---|---|---|---|

| LDO For charging LTO battery which nominal voltage is 2.2 to 2.4V |

Specifications Other points

|

XC6240 / XC6215 |

Low consumption small voltage regulator

VIN: 1.5V~6.0V |

| RESET For monitoring voltage drop of LTO battery which nominal voltage is 2.2 to 2.4V |

Specifications Other points

|

XC6140 / XC6136 |

Ultra-low consumption voltage detector

VIN: 0.4V~6.0V (Detection holding VIN voltage) |

Solution Summary

LTO, a new generation of Li-ion rechargeable batteries with a nominal voltage between 2.2V and 2.4V are now emerging and they offer many benefits over the traditional Li-Ion products.

- Ready for constant voltage charging by LDO. No need for a dedicated expensive CV / CC charging IC.

- Resistant to over-discharge and can be used with simple low voltage detection

- Because it is a battery, it can maintain a constant voltage around 2.2V to 2.3V for a long time. Energy can be used more easily and efficiently than a Supercap, which drops the voltage linearly.

- There are also products that can handle high temperatures such as 70°C and 105°C.

- Reflow / Hot laminating compatible products are also available.

LDO for charging

A low consumption LDO Voltage Regulator is suitable to use with a large capacity secondary batteries as load.

When charging the battery

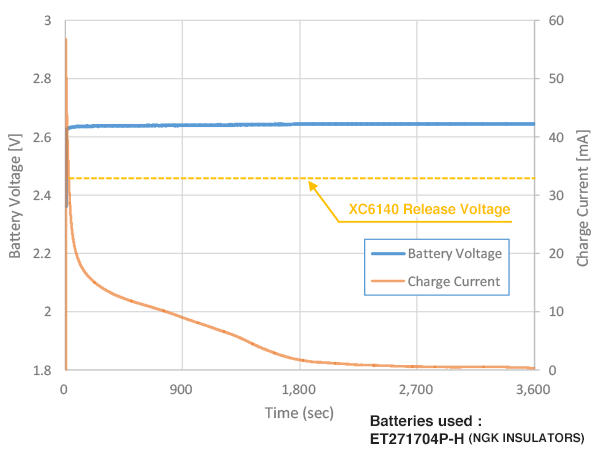

The battery is charged by a constant voltage provided by the LDO Voltage Regulator.

The battery voltage rises to the LDO voltage regulator output voltage in a short period of time after the start of charging, and then the battery is gradually charged.

It is not necessary to detect full charge, and it is generally not necessary to turn off the voltage regulator after full charge.

While using the battery

When the VIN is cut, the CE of the Voltage Regulator becomes ‘Low’ and the LDO turns off. The leakage current from the LTO battery to the LDO becomes very small, this is called as the VOUT sink current.

Reverse current from the battery to VIN is prevented by the SBD, and the pull-down resistor connected to the anode of the SBD switches the VE of the LDO to "L", and puts the voltage regulator into a standby state.

Low-sonsumption voltage regulators

XC6240: VOUT = 2.63V(max 2.7V, including temperature and variations)

XC6215: VOUT = 0.9V~5.0V(0.1V steps)

Voltage Detectors for monitoring battery voltage

Ultra-low consumption voltage detectors can be used to monitor the battery voltage.

There are two main uses

Control of the MCU / next-stage power supply ICs (voltage regulator, step-down/step-up DC/DC) when the battery voltage drops

When the battery voltage drops, the Voltage Detector stoppes the operation of MCU or next-stage power supply ICs.

This prevents malfunctions of the operation of MCU when tbattery voltage drops.

It is important to be able to suppress the quiescent current to a low level after detecting.

Another way to reduce current consumption is to use the output of the voltage detector and Pch SW to cut off the power supply line.

Control of operation starts for system (MCU, next-stage power supply IC)

If the battery voltage reaches or exceeds the release voltage of the voltage detector, a signal is output to start operation of the MCU or next-stage power supply IC.

This makes it possible to prevent the system from repeatedly turning on and off due to internal impedance and inrush current when using a secondary battery with high internal impedance.

A CMOS output type, which does not require a pull-up resistor, is suitable to reduce the quiescent current while operation is stopped.

Ultra-low consumption voltage detectors

XC6140: Detection voltage = 1.6V to 2.2V, release voltage = 2.475V (voltage to release by starting charging by the LDO)

XC6136: Detection voltage = 1.2V to 5.0V, release voltage = detection voltage + 5%

With such a very simple circuit, you can create a rechargeable battery solution.

It is a very easy-to-use solution because it is possible to directly connect a LTO battery with a nominal voltage of 2.2 to 2.4V to the MCU by supporting low voltage operation of the MCU